MOBILE VAPOR DEGASSING, SCRUBBING, MOBILE WATER TREATMENT & PIPELINE EVACUATION SERVICES

DEGASSING & VAPOR CONTROL

Degassing and vapor control are critical to get right – far too important to leave in the hands of inexperienced operators at full service industrial cleaning companies. Since 1992, Envent has specialized in mobile vapor and water treatment and our safety record speaks to the depth of our expertise and the quality of our work. Envent exceeds on all counts.

REFINERY TURNAROUND SERVICES

Time is money during shutdown and turnaround – that’s why companies call Envent for complete turnaround services from vapor control to water treatment during these critical windows of time. As an expert contractor, our most critical factors are regulatory compliance, exposure and safety on behalf of our clients.

MARINE VAPOR RECOVERY

Envent is the North American Leader in marine vapor control and recovery for ships and barges. With mobile systems ready to deploy to ports throughout North America, Envent is the #1 industry leader. Envent has portable dock safety skids and large vapor combustion units capable of fast deployment. Our Portable Marine Vapor Control Systems are USCG Compliant and consist of Envent Mobile Emission Control System (EMECS) and Envent Dock Safety Unit (EDSU) units.

SCRUBBERS & ODOR CONTROL

Since 1992, Envent Corporation has been North America’s #1 leader of mobile vapor scrubbing. With exceptional vapor scrubbing equipment, technicians, and logistics, industrial and commercial companies as well as municipal organizations contact our team to ensure that vapor scrubbers and odor emissions are handled skillfully, safely, and in full compliance with all local, state and national regulations.

WATER TREATMENT SERVICES

We provide turnkey solutions for soil and groundwater remediation and treatment. We work in a range of industries, including petrochemical, environmental engineering, industrial and oilfield services. Envent also handles dewatering duties at large construction sites throughout the United States. Envent operates the largest fleet of portable remediation systems in the country, and our crews can respond 24/7 to spill emergencies anywhere in the United States.

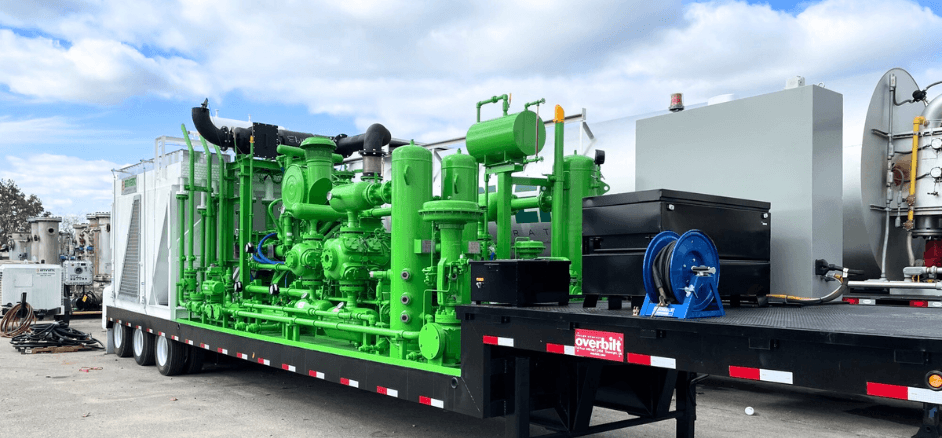

Pipeline Evacuation & Natural Gas Compression Services

In 2021, Envent added a fleet of state-of-the-art mobile transmission and distribution natural gas cross-compression units. These units, strategically staged at our offices throughout North America allow us rapid strike response to methane mitigation projects for our transmission, distribution and pipeline customers to recapture the natural gas and achieve net ZERO emissions and meet the latest MEGA Rule standards.. These units are capable of drawing down and evacuating methane at 1400 PSIG to < 5 PSIG with hours. This method not only saves time and enhances safety, but also helps you save money while safeguarding the environment.

DEGASSING & VAPOR CONTROL

Degassing and vapor control are critical to get right – far too important to leave in the hands of inexperienced operators at full service industrial cleaning companies. Since 1992, Envent has specialized in mobile vapor and water treatment and our safety record speaks to the depth of our expertise and the quality of our work. Envent exceeds on all counts.

REFINERY TURNAROUND SERVICES

Time is money during shutdown and turnaround – that’s why companies call Envent for complete turnaround services from vapor control to water treatment during these critical windows of time. As an expert contractor, our most critical factors are regulatory compliance, exposure and safety on behalf of our clients.

MARINE VAPOR RECOVERY

Envent is the North American Leader in marine vapor control and recovery for ships and barges. With mobile systems ready to deploy to ports throughout North America, Envent is the #1 industry leader. Envent has portable dock safety skids and large vapor combustion units capable of fast deployment. Our Portable Marine Vapor Control Systems are USCG Compliant and consist of Envent Mobile Emission Control System (EMECS) and Envent Dock Safety Unit (EDSU) units.

SCRUBBERS & ODOR CONTROL

For nearly 25 years, Envent Corporation has been North America’s #1 leader of mobile vapor scrubbing. With exceptional vapor scrubbing equipment, technicians, and logistics, industrial and commercial companies as well as municipal organizations contact our team to ensure that vapor scrubbers and odor emissions are handled skillfully, safely, and in full compliance with all local, state and national regulations.

WATER TREATMENT SERVICES

We provide turnkey solutions for soil and groundwater remediation and treatment. We work in a range of industries, including petrochemical, environmental engineering, industrial and oilfield services. Envent also handles dewatering duties at large construction sites throughout the United States. Envent operates the largest fleet of portable remediation systems in the country, and our crews can respond 24/7 to spill emergencies anywhere in the United States.

Pipeline Evacuation & Natural Gas Compression Services

In 2021, Envent added a fleet of state-of-the-art mobile transmission and distribution natural gas cross-compression units. These units, strategically staged at our offices throughout North America allow us rapid strike response to methane mitigation projects for our transmission, distribution and pipeline customers to recapture the natural gas and achieve net ZERO emissions and meet the latest MEGA Rule standards.. These units are capable of drawing down and evacuating methane at 1400 PSIG to < 5 PSIG with hours. This method not only saves time and enhances safety, but also helps you save money while safeguarding the environment.